Promedia systems / Solidworks / Solidworks Simulation

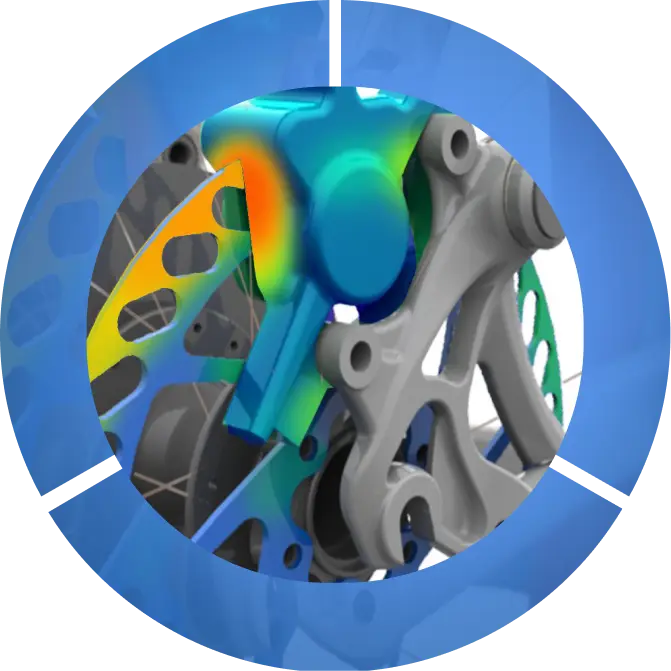

What is Solidworks Simulation?

Solidworks Simulation extensively works on the FEM or Finite Element Method of testing and computing in the process of analyzing a product’s behaviour. This programming is embedded into the SolidWorks CAD software, equipping the designers and engineers to quickly test or modify their design tactfully before circulating to the other teams working on the product development. Empower yourselves with the seamless experience to speed up the prototype phase of your product with SolidWorks Simulation.

How accurate are the results?

SOLIDWORKS Simulation delivers highly accurate results when models are set up correctly with precise material properties and boundary conditions. It is validated against real-world tests, ensuring reliability for engineering applications. With advanced solvers and mesh refinement, it provides results within 5-10% of physical testing. Many industries trust it to optimize designs and reduce prototyping costs efficiently.

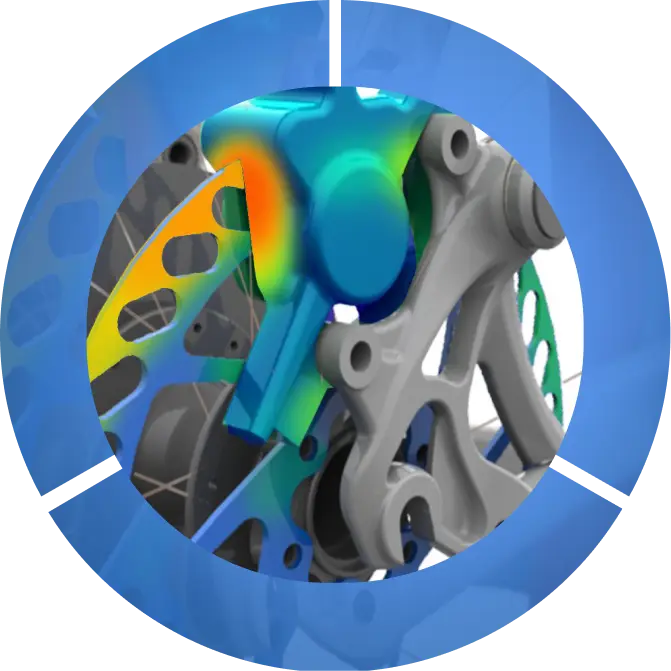

Features of our Most Sought After SolidWorks Simulation Tools

Promedia Systems is a leading brand in dealing with top-quality SolidWorks Simulation programming tools. Our expert team help set up your workstations with the following features customized for your intricate needs.

Linear Stress Analysis

Non-linear Stress Analysis

Finite Element Analysis

Dynamic Analysis

Frequency Analysis

Thermal Analysis

This feature is extensively used to maintain the temperature and heat transfer within the same component or in between other components working together.

Frequency Analysis

Thermal Analysis

This feature is extensively used to maintain the temperature and heat transfer within the same component or in between other components working together.

Fatigue Analysis

The SolidWorks Simulation runs load analysis to check the failures with repeated checks during the developmental stage of the product.

Structural Optimization

Buckling Analysis

Vibration Analysis

Structural Optimization

Buckling Analysis

Benefits of Opting for our SolidWorks Simulation Tools

1. Accurate & Reliable Analysis

2. Cost & Time Savings

3. Optimized Product Design

4. Advanced Nonlinear & Dynamic Simulation

5. User-Friendly Interface & Seamless Integration

Fully integrated with SOLIDWORKS, our simulation tools provide an intuitive, easy-to-use interface. This allows engineers and designers to conduct simulations without needing specialized training, making the process efficient and accessible.

6. Enhanced Innovation & Design Iterations

Best Offerings of SolidWorks Simulation Packages by Promedia Systems

- SolidWorks Simulation Standard

- Basic structural analysis tools

- Stress and displacement analysis

- Motion simulation for assemblies

- Contact analysis between parts

- SolidWorks Simulation Professional

- All features of the Standard package

- Thermal analysis (steady-state and transient)

- Frequency and buckling analysis

- Fatigue analysis for product durability

- Topology optimization

- Simulation Premium

- All features of the Professional package

- Nonlinear static and dynamic analysis

- Composite material analysis

- Advanced dynamic response

- SolidWorks Plastic

- Plastic injection molding simulation

- Avoid defects in plastic part design

- Optimize mold designs

- SolidWorks Flow Simulation

- Computational Fluid Dynamics (CFD) analysis

- Heat transfer and fluid flow simulations

- HVAC and electronics cooling analysis

- Simulation Premium

Why Choosing Promedia Systems for the Best SolidWorks Simulation

- Latest advancements in SolidWorks Plastics by injection molding simulation

- Training and Support for using the 3Dexperiencetechnology while running simulation

- Onboarding, Analysis and relevant Software Implementation

- Industry Knowledge and Experience

- Local language tech support

- Industry Knowledge and Experience

Contact Promedia Systems today

For a tailor-made analysis of your product and its conditions through SolidWorks Simulation and how Promedia Systems can propel your business to new levels.